*illustrative photo

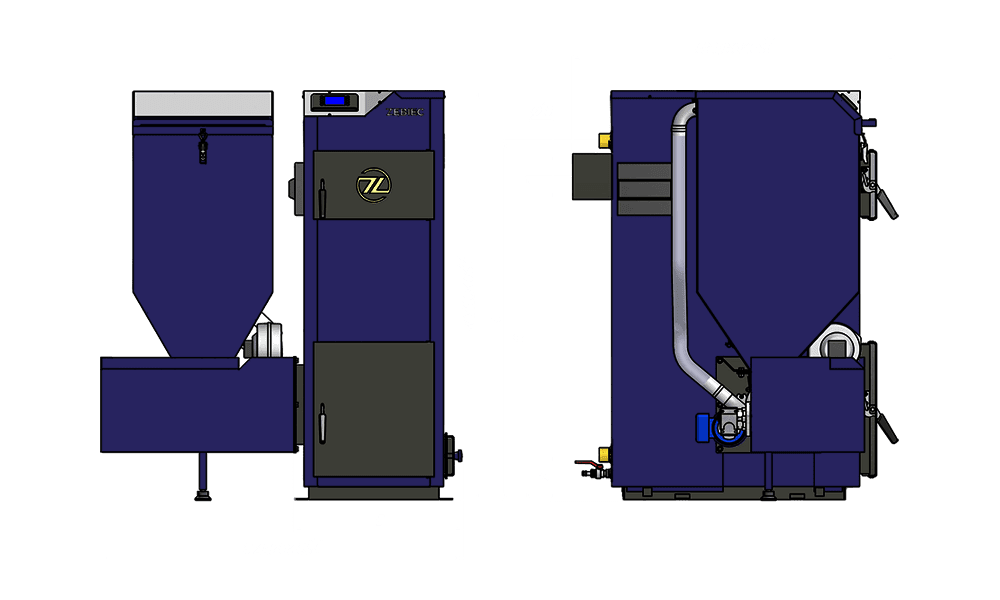

TOPAZ

Archival offer

Class 5 boiler for eco-pea coal

A state-of-the-art, eco-pea coal heating boiler which meets the stringent criteria of the standard PN-EN 303-5:2012 in respect of exhaust emissions and efficiency. It was tested by the Institute for Chemical Processing of Coal in Zabrze (accreditation by the Polish Centre for Accreditation No. AB 081) and fulfilled the performance requirements specified by the said standard, receiving CLASS 5 (certificate No. 35/2017).

96.1% – high thermal efficiency

The 3-path design of the heat exchanger plus excellent insulation of the boiler ensure up to 96.1 % efficiency. The use of auxiliary components, such as turbulators, a spiral deflector, minimises dust emission.

Maintenance-free heating using coal eco-peas

The PID algorithm used on the LIDER PID DYNAMIC controller automatically controls the quantity of the fuel fed in and the induced air flow. The chief advantages of this kind of control are:

- the stability of the set temperature, regardless of momentary changes in heat demand,

- a considerably reduced release of carbon monoxide and other harmful substances into the atmosphere,

- much longer periods between cleanouts.

Modern solutions in eco-pea coal boiler

The boiler features many unique patented solutions. They make the operation of the boiler more efficient and enhance its safety and performance.

The most important solutions include:

- an auger-rotation sensor – utility model No. 64607,

- a hopper-drying system – utility model No. 65550,

- a rotary connector – utility model No. 123722 (available at extra an charge).

Fuel dryer system.

Certified boiler plates P265GH.

60-month warranty for leak-tightness of the water jacket.

24-month warranty for fault-free operation.

Automatic operation

High thermal efficiency reaching 96.1%

Retort air-pressure balancing system

Ceramic burning chamber.

Deflector

Increased safety of operation through the use of sensors.

Auger-rotation sensor.

Ease of use.

As an additional option

Cooperation with the weather regulator

Boiler control via the Internet

Boiler control using the room panel

|

| Pellet peas, grade II, type 31.2 (8–20 mm) |

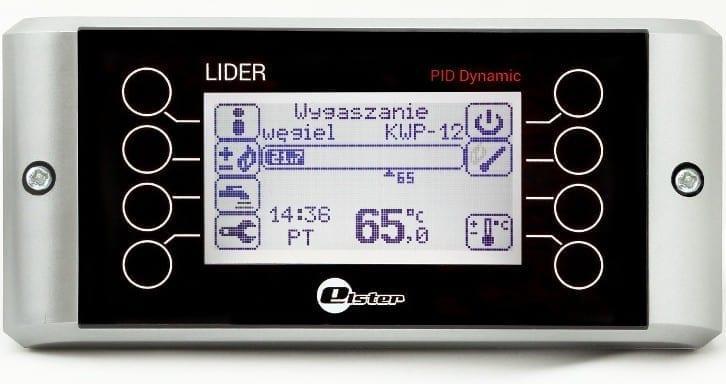

LIDER PID DYNAMIC controller

The boiler operation is controlled by a modern LIDER PID DYNAMIC controller with the feature of controlling 4 pumps, a three- or four-way mixing valve. And several independent heating circuits, controlling via room panel and Internet, weather-based controlling etc.

Additional equipment

- ROOMSTER II RTX room controller

- ETH-100 Internet module

- RTx Lider wireless communication module

- LIDER KTY Weather sensor

- User manual – TOPAZ 24

- User manual – TOPAZ 13 17 21

- Controller user manual – LIDER PID DYNAMIC

- Energy label – TOPAZ 13

- Energy label – TOPAZ 17

- Energy label – TOPAZ 21

- Energy label – TOPAZ 24

- TOPAZ 13 17 21 – product card

- TOPAZ 24 – product card

- EC Declaration of Conformity

- Certificate – TOPAZ 13

- Certificate – TOPAZ 17

- Certificate – TOPAZ 21

- Certificate – TOPAZ 24

- Certificate – TOPAZ 25

- Attestation – TOPAZ 13

- Attestation – TOPAZ 17

- Attestation – TOPAZ 21

- Attestation – TOPAZ 24

| BOILER | Height | Width | Depth | A [mm] | B [mm] | C [mm] | D [mm] | E [mm] |

| TOPAZ 13 | 1175 | 1246 | 1104 | 156 | 875 | 997 | 159 | 555 |

| TOPAZ 17 | 1275 | 1246 | 1104 | 156 | 975 | 1097 | 159 | 555 |

| TOPAZ 21 | 1349 | 1246 | 1173 | 156 | 1050 | 1173 | 159 | 555 |

| TOPAZ 24 | 1424 | 1256 | 1130 | 156 | 1125 | 1250 | 159 | 585 |

| Detailed data | J.m. | TOPAZ 13 | TOPAZ 17 | TOPAZ 21 | TOPAZ 24 | |

| Energy efficiency class | B | B | B | B | ||

| Rated thermal output | kW | 13 | 17 | 21 | 24 | |

| Energy efficiency ratio | 86 | 86 | 85 | 87 | ||

| Operating range | kW | 3,9-13 | 5,1-17 | 6,3-21 | 7,2-24 | |

| Thermal efficiency | % | do 95,9 | do 96,1 | do 94,1 | do 95,7 | |

| Single-charge sustained combustion at rated/minimal power* | h | 54-179 | 49-162 | 46-152 | 34-110 | |

| Hopper capacity* | dm3/kg | 135/108 | 160/128 | 185/148 | 200/160 | |

| Boiler water capacity | dm3 | 80 | 90 | 100 | 110 | |

| Min. required draught | Pa | 20 | 20 | 25 | 25 | |

| Min. chimney height | m | 5 | 5 | 7,5 | 7,5 | |

| Min. chimney cross-section area | cm x cm Φ cm | 20 x 14 Φ 18 | 20 x 14 Φ 18 | 20 x 14 Φ 18 | 20 x 14 Φ 18 | |

| Flue diameter | mm | Φ 159 | Φ 159 | Φ 159 | Φ 159 | |

| Threaded connection pipes | mm | Φ 48,3×4 (1 1/2″) | Φ 48,3×4 (1 1/2″) | Φ 48,3×4 (1 1/2″) | Φ 48,3×4 (1 1/2″) | |

| Max. operating pressure | bar | 1,5 | 1,5 | 1,5 | 1,5 | |

| Boiler weight without water | kg | 490 | 520 | 600 | 650 | |

| Boiler class as per PN EN 303-5:5:2012 | 5 | 5 | 5 | 5 | ||

| Ecodesign | yes | yes | yes | yes |

| ZĘBIEC boilers | Thermal output | Heated floor area [m2], based on the heat transfer coefficient of the walls (insulation) | |||

| U 1 [W/m2K] | U ~ 0,7 [W/m2K] | U ~ 0,5 [W/m2K] | U ~ 0,3 [W/m2K] | ||

| no insulation | ~5cm styrofoam | ~8cm styrofoam | ~10cm styrofoam | ||

| TOPAZ 13 | 13 | 110 | 130 | 160 | 200 |

| TOPAZ 17 | 17 | 145 | 170 | 200 | 250 |

| TOPAZ 21 | 21 | 180 | 210 | 250 | 355 |

| TOPAZ 24 | 24 | 215 | 250 | 295 | 385 |