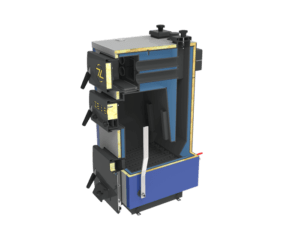

*Illustrative photo

KWKD

Lower combustion boiler

The KWK type boiler is a heating unit with lower combustion of long-flame solid fuels. It was designed with the participation of the Research Institute, so it is characterised by high efficiency. Boilers of this type enjoy great popularity due to easy handling. They are great for the heating of houses, garages, utility buildings or commercial spaces.

Easy to use

The economical and fault-free operation of the boiler depends on its correct parameters and the constant control of its work. Burning temperature can be easily adjusted by means of a knob on the hinged flap located on the ash pan door or by means of an automatic draught regulator. When he large combustion chamber is topped up and correct combustion parameters are set, the boiler will produce heat for many hours, without any intervention.

Rapid heat transfer

The KWKD type boiler combines the best solutions which enhance its efficiency, which help to provide heat in a short time. The compact design of the exchanger and high grade materials as well as a fixed water grate guarantee a high thermal output despite the boiler’s small dimensions. The heavy, fixed grate is quicker to deliver heat from the fuel to the circulating water, and this enhances the thermal efficiency of the unit. Heat dissipation is effectively reduced by means of an insulation mantle made with layers of steel lined with mineral wool. The thermal efficiency of KWKD boilers reaches 82%.

Reliable design

The design of these boilers is solid and resistant to high temperatures. The use of proven materials, such as boiler steel, guarantees stable operation for many years. Satisfactory insulation prevents heat loss and ensures maximum retrieval of energy, which help the boiler to reach high levels of thermal output quickly. KWKD boilers made by ZGM ZĘBIEC SA ensure a long service life free from unexpected failures.

Large combustion chamber

Combustion is controlled by means of an automatic draught regulator* or manually (*as an option at extra charge)

High combustion efficiency, up to 82%

Certified boiler plates P265GH

Quick and effective ash removal thanks to a cast iron, mobile grate.

Easy and quick operation.

36-month warranty for the leak-tightness of the water jacket

24-month warranty for service life and efficient operation

|

|

|

| Hard coal | Coke |

Automatic

By means of a draught regulator

Manual

By means of a screw adjusting the position of the flap in the lowest door

| Boiler | Height | Width | Depth | A | B | C | Flue | Burning chamber | Charging hole | F | ||||

| D | E | height | width | depth | width | height | ||||||||

| KWKD 15 | 1051 | 444 | 717 | 269 | 906 | 1090 | 140 | 110 | 330 | 338 | 275 | 212 | 167 | 507 |

| KWKD 22 | 1217 | 506 | 745 | 290 | 1062 | 1252 | 160 | 130 | 370 | 400 | 275 | 317 | 197 | 569 |

| Item | Detailed data | UOM | Boiler size | ||

| 1. | Rated thermal output | kW | 15 | 22 | |

| 2. | Fuel | hard coal, nut coal II | |||

| 3. | Heat efficiency at rated power | % | up to 82 | up to 82 | |

| 4. | Heat output regulation range | % of rated output | 30 ¸ 100 | 30 ¸ 100 | |

| 5. | Max. leaving water temperature | oC | 95 | 95 | |

| 6. | Max. operating pressure | MPa | 0,15 | 0,15 | |

| 7. | Min. return water temperature | oC | 40 | 40 | |

| 8. | Max. operating pressure | bar | 1,5 | 1,5 | |

| 9. | Required draught | Pa | >24 | >25 | |

| 10. | Min. chimney cross-section area as per PN-89/B-10425 | cm x cm

Æ cm |

14 x 14

Æ 16 |

20 x 14

Æ 18 |

|

| 11. | Flue dimensions | mm | 140 x 110 | 160 x 130 | |

| 12. | Min. chimney height | m | 5 | 5 | |

| 13. | Water connections, inlet/outlet (threaded) | mm | Æ60,3 x 4 (2”) | Æ60,3 x 4 (2”) | |

| 14. | Charge capacity of the burning chamber | dm3 | 42 | 50 | |

| 15. | Stoking door dimensions | mm | 175 x 220 | 205 x 324 | |

| 16. | Single-charge combustion at rated power | godz. | > 5 | > 6 | |

| 17. | Boiler water capacity | dm3 | ~ 58 | ~ 76 | |

| 18. | Weight of empty boiler | kg | 224 | 290 | |

| 19. | Overall dimensions | Height | mm | 1051 | 1217 |

| Width | mm | 444 | 506 | ||

| Depth

with return duct (flue) |

mm | 717 | 745 | ||

| ZĘBIEC boilers | Thermal output [kW] | Heated floor area [m2], based on heat transfer coefficient of walls (insulation) | |||

| U > 1 [W/m2K] | U ~ 0,7 [W/m2K] | U ~ 0,5 [W/m2K] | U ~ 0,3 [W/m2K] | ||

| no insulation | ~5 cm styrofoam | ~8 cm styrofoam | >10 cm styrofoam | ||

| KWKD 15 | 15 | 130 | 150 | 175 | 230 |

| KWKD 22 | 22 | 195 | 220 | 260 | 340 |

Draught regulator

A draught regulator in solid-fuel boilers is a thermostatically operated device for controlling the water temperature in the boiler.

The thermostat head of the regulator monitors the water temperature in the boiler and via levers and a chain moves a flap to increase or reduce the airflow into the hearth.